Natural gas generator set

Natural gas generator sets are ignition gas engines that use natural gas and other high calorific value gases as fuel

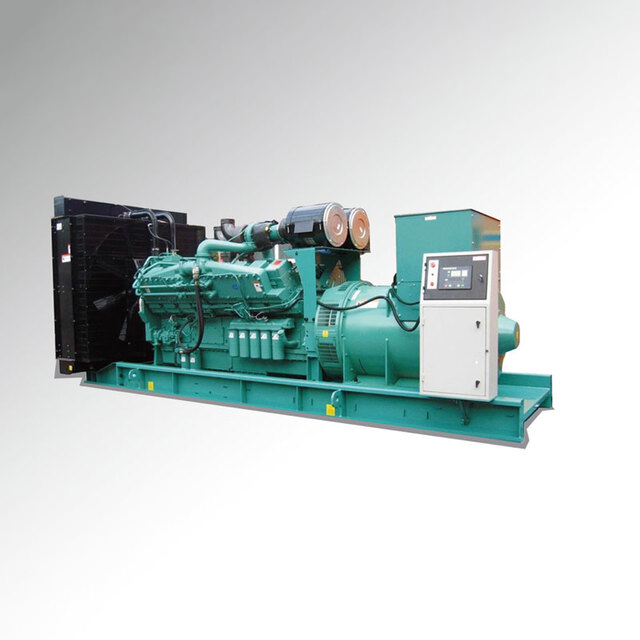

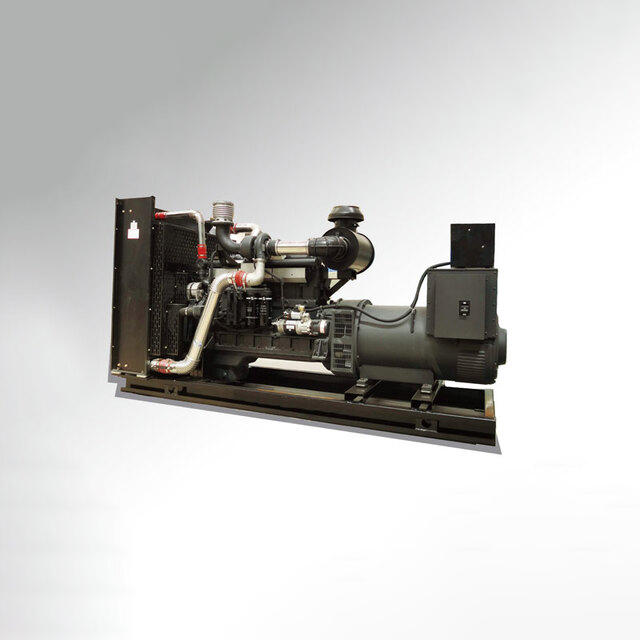

[natural gas generator sets] Natural gas generator sets

are mainly matched with Siemens technology generators. The engine part is a new product developed on the basis of the T12V190 gas engine, and the two models have a high degree of commonality. This engine adds a supercharging system and an intercooling system on the basis of the T12V190 non-supercharged model. The cooling system adopts a high and low temperature cycle separation method. The high temperature cycle cools the high temperature parts such as the cylinder, body, and cylinder head, and the low temperature cycle cools the supercharged gas, air, and oil cooler.

In recent years, the rapid development of the national economy has provided continuous impetus for the steady and rapid development of China's power industry. The national electricity demand has grown rapidly, and the power supply capacity has steadily increased. As an important equipment in the power industry, the market for natural gas generator sets has increased sharply. At

the end of 2011, the sales revenue of the generator and

generator set manufacturing industry reached 290.069 billion yuan, and the average annual growth rate of sales revenue in the industry in the past five years was 47.63%. While the generator and generator set manufacturing industry is developing rapidly, the pace of product structure adjustment in the industry will also accelerate. The market share of natural gas generator sets will shrink, while the market share of hydropower, nuclear power, and wind power units will increase accordingly. In addition, in the future, generator sets will also develop in the direction of energy saving, environmental protection, lightweight, miniaturization, and beautiful appearance. Products with these properties will have a larger market.

Selection of gas, oil and coolant:

Before using the natural gas generator set engine, the appropriate specifications of natural gas, oil and coolant should be selected according to the specific environment and conditions of use. Whether the selection is appropriate or not has a great impact on the performance and service life of the natural gas generator set engine.

1. Requirements for the use of gas by natural gas generator sets:

The fuel of the gas engine is mainly natural gas, and oil field associated gas, liquefied petroleum gas, biogas and other combustible gases can also be used. The gas used should be dried and dehydrated to achieve the absence of free water, crude oil and light oil. Its lower calorific value should not be less than 31.4mj/m3, the total sulfur content should not exceed 480mg/m3, and the hydrogen sulfide content should not exceed 20mg/m3. In addition, the natural gas transmission pressure is within the range of 0.08-0.30MAP.

2. Engine oil used in natural gas generator sets

Engine oil is used to lubricate the moving parts of the natural gas engine and to cool and dissipate heat, remove impurities and prevent rust on these moving parts. In addition to affecting the performance and service life of the gas engine, its quality has a certain impact on the service life of the engine oil. Therefore, the appropriate engine oil should be selected according to the ambient temperature of the gas engine of the natural gas generator set. Natural gas engines should use special engine oils such as 15W40CD or 15W40CC as much as possible.

3. Coolant used in natural gas generator sets:

The coolant used for direct cooling of the engine in the cooling system is usually clean fresh water, rainwater or clarified river water. When the natural gas engine is used in an environment below 0 degrees, the coolant should be strictly prevented from freezing, causing the parts to crack. Antifreeze with an appropriate freezing point can be used according to the temperature or hot water can be added before starting, but the water should be drained immediately after stopping.

You Might Also Like